- Home

- Metronomo.Net

- Monitoring 4.0

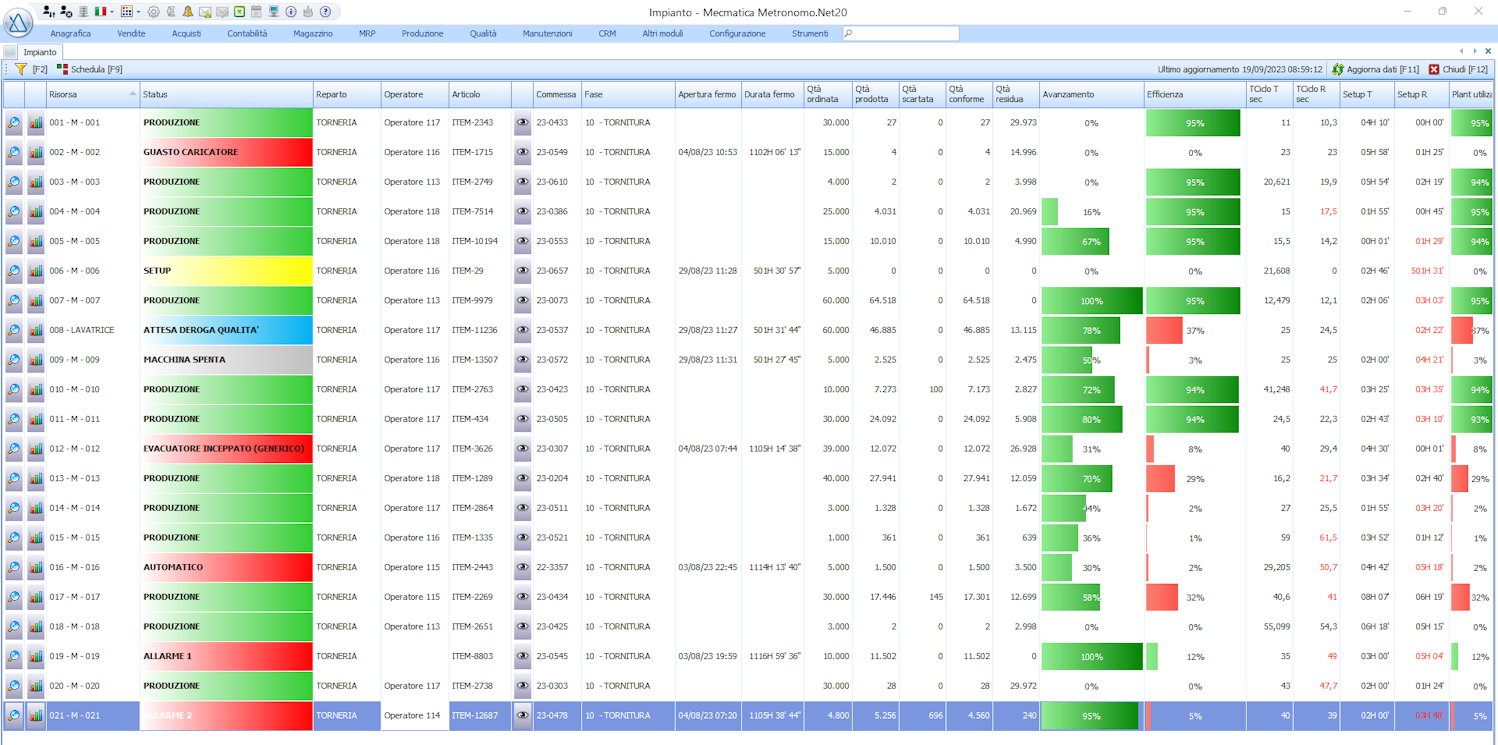

Continuous production control - anywhere and in real time

Our MES 4.0 solution is a production asset monitoring module: it provides all production data of the manufacturing assets connected to the system in real time.

Connecting machines as well as scheduling and planning in synchronous mode allows the company's production progress to be kept under control: any discrepancy between the estimated and actual deadlines is reported in real time to the production managers, so that they can intervene and correct any errors or improve efficiency.

Advantages

Act in time to avoid production stops

This module allows for the continuous surveillance of production assets - anytime, anywhere and in real time. Some further related benefits are:

Immediate detection and reporting of discrepancies between theoretical and measured timings, such as cycle time, machine set-up and positioning time

Automatic costing of the monitored production orders

Instant detection and reporting of machine downtime, be that an alarm or production downtime

Historical archive of all production data and recorded timings

Automatic calculation of individual machine efficiency, statistical analyses and indices on individual resource models

Checking the machinery status and linking it to any acoustic signals to communicate any unmanaged stoppages or the need to carry out quality checks by setting up information monitors on the shop floors

Collection of data that are stored and analysed so that production efficiency statistics can be created per individual asset, by shop floor or for the entire company

Connection both wireless and via cable, as per your requirements.